In the fast-moving global race for semiconductor and AI leadership, Vietnam is emerging as a dynamic new player. At the heart of this transformation stands VSAP Lab – Vietnam Semiconductor Advanced Packaging Lab-Fab – the country’s first fully funded startup dedicated to advanced packaging research, design, prototyping, and pilot manufacturing.

Based in Da Nang, VSAP Lab represents a bold step toward building a complete semiconductor ecosystem in Vietnam — a foundation that connects research, innovation, and industrialization through its pioneering “Lab-Fab” model.

From Vision to Reality: Vietnam’s First Advanced Packaging Lab-Fab

VSAP Lab was founded with a clear vision: to bridge the gap between laboratory research and industrial fabrication in the semiconductor value chain.

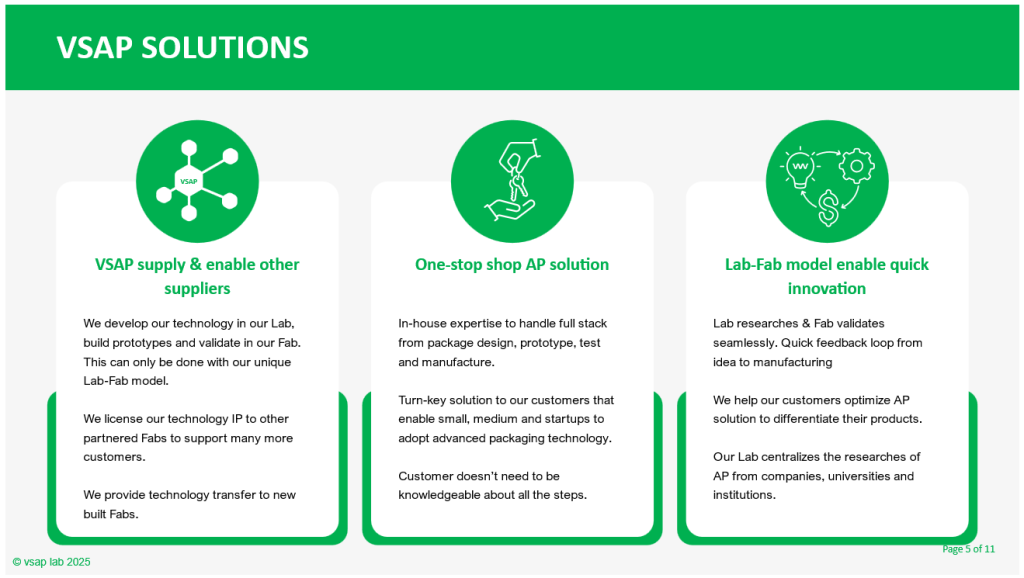

The Lab-Fab model — successfully implemented in global technology hubs such as IMEC in Belgium and Fraunhofer in Germany — accelerates technology transfer by allowing new ideas to be validated and scaled in a single, integrated environment.

In Vietnam, this model takes on strategic importance. By linking R&D laboratories with pilot-scale production lines, VSAP Lab is creating a platform where innovators, engineers, and manufacturers can collaborate to develop packaging technologies that meet global standards while being adapted to local capabilities.

Comprehensive Solutions for a Fast-Evolving Industry

Unlike most traditional packaging service providers, VSAP Lab offers a complete “one-stop” solution for advanced semiconductor packaging — from design simulation and materials research to prototyping, reliability testing, and small-batch manufacturing.

Its core technological portfolio includes:

- Flip-Chip BGA (FCBGA): Optimized for cost-performance balance in consumer and industrial applications.

- Fan-Out Wafer-Level Packaging (FOWLP): Thin, high-performance packages ideal for mobile, IoT, and AI edge devices.

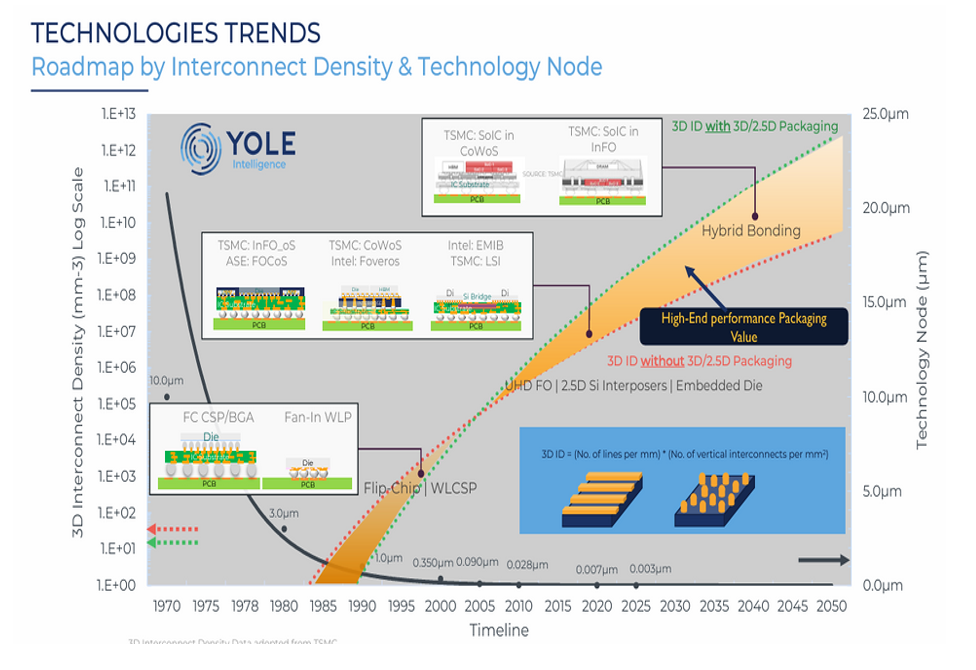

- 2.5D and 3D Packaging: Enabling chip stacking and heterogeneous integration for high-performance computing (HPC) and artificial intelligence workloads.

- Wafer-to-Wafer / Die-to-Wafer Bonding: Cutting-edge bonding methods that increase bandwidth, reduce power consumption, and enhance interconnect density.

With this integrated model, VSAP Lab can shorten the time-to-market for new chips, reduce development risks, and deliver tailored solutions for each customer — from startups designing AI accelerators to established electronics manufacturers exploring chiplet architectures.

Why Vietnam, Why Now

According to Yole Group, the global advanced packaging market is expected to grow by over 10% annually, reaching nearly US $80 billion by 2028, fueled by surging demand from AI, 5G, IoT, and autonomous systems.

Yet the global supply chain remains highly concentrated in only a few regions, dominated by major players such as TSMC, ASE, Amkor, and Intel. Capacity shortages, long lead times, and rising costs have opened a crucial window for new entrants to localize production closer to emerging markets.

Vietnam — with its young engineering workforce, growing policy support, and strategic location in Southeast Asia — is uniquely positioned to become a new node in the global packaging network.

VSAP Lab was created precisely to seize this opportunity. Its mission is to empower Vietnam’s semiconductor industry to participate in higher-value stages of the global value chain, starting with advanced packaging — the critical intersection of design and manufacturing where innovation meets scalability.

Technology, People, and Purpose

At its core, VSAP Lab combines technical excellence, entrepreneurial spirit, and a commitment to sustainable innovation.

The company brings together experienced engineers and researchers in microelectronics, materials science, and process engineering, supported by young Vietnamese talent eager to master next-generation semiconductor technologies.

Its facility at Da Nang Software Park 2 will include both laboratory R&D areas and a pilot cleanroom line designed to validate packaging processes such as wafer-level fan-out, underfill, molding, and reliability testing. The cleanroom infrastructure will follow international Class 1000–10000 standards, allowing VSAP Lab to develop, test, and demonstrate high-performance packaging solutions for local and global partners.

A Three-Pillar Business Model

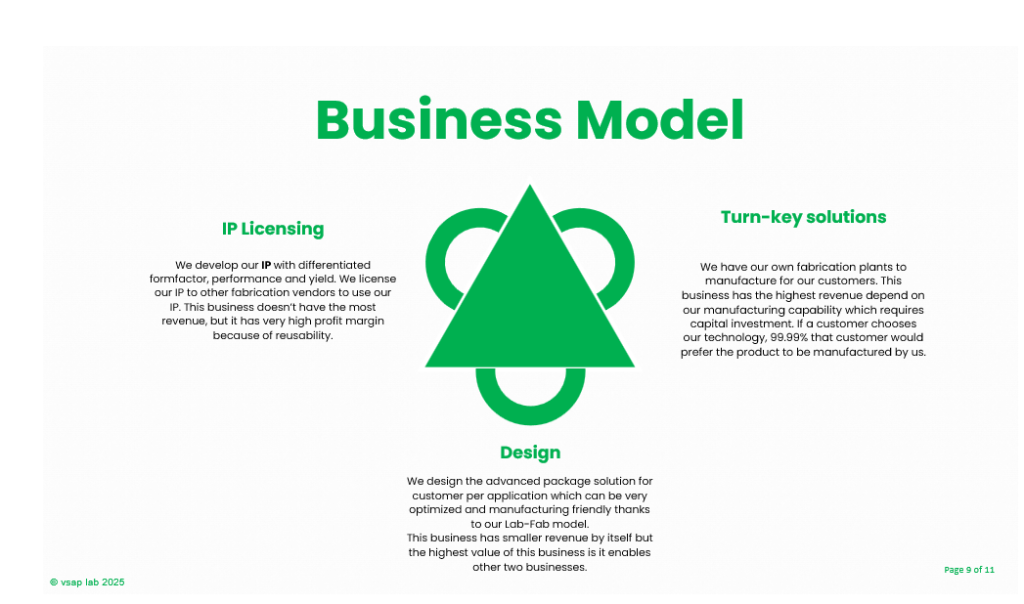

VSAP Lab’s operations are built on three interconnected pillars, ensuring both technological depth and commercial sustainability:

- IP Licensing

The Lab develops proprietary process and design IP with optimized form factors, yields, and performance. These technologies can be licensed to partner fabs across Vietnam and abroad, creating scalable revenue through high-margin intellectual property reuse. - Design Services

VSAP Lab offers customized package-level design solutions tailored to specific applications — from AI accelerators and automotive sensors to industrial controllers and photonics devices. This service not only helps customers optimize performance and cost but also anchors long-term partnerships built on shared innovation. - Turnkey Manufacturing

Leveraging its own pilot fabrication lines, VSAP Lab provides a complete “design-to-product” service. Customers can rely on VSAP’s expertise in process validation and small-batch production before scaling to high-volume manufacturing with local or international partners.

This tri-pillar model enables a continuous innovation loop — research in the Lab, validation in the Fab, and technology transfer to industrial partners — creating a sustainable, scalable business ecosystem.

A Symbol of Vietnam’s “Make in Vietnam” Spirit

Beyond technology, VSAP Lab embodies the national ambition to move from “Make in Vietnam” to “Innovate in Vietnam.”

Its visual identity reinforces that message: the VSAP Lab logo features five interconnected silicon modules, symbolizing precision, unity, and the convergence of multiple disciplines. The green color palette represents sustainability, growth, and the country’s aspiration to build a greener semiconductor industry.

The design reflects harmony between research and manufacturing, technology and humanity, mirroring Vietnam’s commitment to pursue innovation responsibly and sustainably.

Da Nang – The Emerging Silicon Bay

Da Nang City provides the ideal environment for this vision.

As a designated innovation and digital transformation hub, Da Nang is rapidly investing in high-tech infrastructure, software parks, and AI-ready data centers. The city’s strategic location, supportive policies, and expanding technical workforce make it a natural home for the country’s first Advanced Packaging Lab-Fab.

Through VSAP Lab, Da Nang aims to position itself as Vietnam’s “Silicon Bay” — a convergence point where academia, government, and industry collaborate to accelerate national capabilities in semiconductors and AI hardware.

Enabling Vietnam’s Semiconductor Future

VSAP Lab stands for more than a company; it represents a movement toward self-reliance, innovation, and sustainability in one of the world’s most critical industries.

By fostering collaboration between local engineers and international experts, the Lab-Fab initiative will cultivate a new generation of Vietnamese semiconductor talent and accelerate domestic R&D capacity.

In a world increasingly defined by technology and connectivity, semiconductors are the backbone of every innovation — from AI to clean energy to smart manufacturing. Through VSAP Lab, Vietnam is taking its first decisive step toward not only participating in this global ecosystem but shaping its future.

A New Chapter Begins

As global companies diversify their supply chains and governments invest heavily in semiconductor resilience, Vietnam’s entry into advanced packaging marks a historic turning point.

VSAP Lab embodies this momentum — a blend of ambition, engineering excellence, and national pride.

From its base in Da Nang, VSAP Lab is writing a new chapter for Vietnam’s high-tech future:

Innovated in the Lab. Validated in the Fab. Made for the World.

(Phuc Le – Director PR & Business Development)

Tiếng Việt

Tiếng Việt